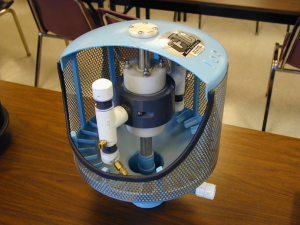

Rotary Drum Screen

|

Advantages

- Proven fish protection

- Self-cleaning by rotation

- Passes debris downstream

|

Disadvantages

- Susceptible to direct hits from large debris

- Large civil works required

- Seals require significant maintenance

- Susceptible to abrasions by sand – mesh requires periodic replacement

- Need control to maintain submergence between 65% and 85%

|

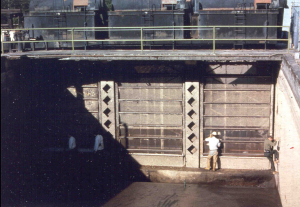

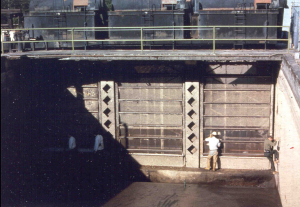

Vertical Fixed Plate Screen

|

Advantages

- Easy to see

- Mechanically simple

- Can be installed on river’s edge – small screens

- No bypass required

- Can use profile wire

- Mechanical/brush cleaning usually effective

- Air burst cleaning system is on back side of screen

- Cleaning is started by timer or head loss

|

Disadvantages

- Must be cleaned mechanically

- Large bypass flows required

- Brush arms can be damaged by large debris

- Circular air burst cleaners do not clean entire screen

|

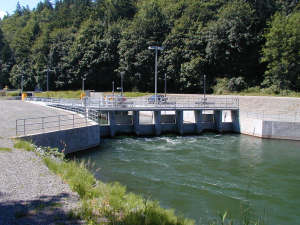

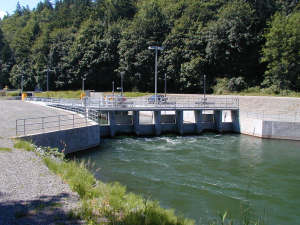

Vertical Traveling Screen

|

Advantages

- Small screens can be installed on riverbank

- Compact civil works

- Self-cleaned by rotation

- Jet sprays provide additional cleaning

|

Disadvantages

- Mechanically complex

- Seals can be a problem

- Make sure meets all NMFS criteria (old styles may not)

|

Non-Vertical Fixed Plate Screen – Coanda

|

Advantages

- No moving parts

- No bypass required if built in-river

|

Disadvantages

- Self-cleaning may not be reliable

- Risk of fish injury/mortality on screen during low flow

- Must raise and control water surface

- Unreliable flow rate control

- Adult upstream passage concerns

- Potential issues with hydraulic gradients

|

Horizontal Screens – FCA

|

Eicher Screen

|

| Modular Inclined Screens

|

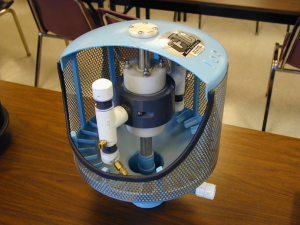

End-Of-Pipe (Pump) Intake Screens

|

Fixed Cylindrical Screens

|

Advantages

- Good option for deep intakes

- Air burst cleaning system can be made to be effective

- Some off-the-shelf models with water backwash systems meet NMFS criteria for active screens

|

Disadvantages

- Out of sight, out of mind

- Need sweep velocity to transport debris from screen site

- Air burst systems on large installations don’t always clean entire screen – especially the bottom

- Long, stringy vegetation is a problem on small pump screens

|

Pump Screens

|